The thrill of creating a one-of-a-kind bikini or swimsuit is unmatched. You have the perfect pattern, the most vibrant colors, and a design that’s uniquely you. But how do you ensure that stunning design stays brilliant and feels amazing wear after wear? The secret lies in the printing method.

When it comes to swimwear, not all printing is created equal. The unique demands of performance fabric—constant stretching, and exposure to sun, chlorine, and saltwater—mean that only the best technology will do.

The two primary methods you’ll encounter are Dye-Sublimation and Heat Transfer.

By the end of this guide, you will understand exactly how each method works, their critical pros and cons for swimwear, and which one is the undisputed champion for bringing your custom designs to life.

The Quick Answer

For high-quality, durable, and vibrant custom swimwear, dye-sublimation is the superior choice. It infuses the design directly into the fabric, resulting in a print you can’t feel, that won’t crack or peel, and that perfectly withstands the demanding environment of sun, chlorine, and salt.

- Choose Sublimation for: Vibrant, permanent designs, a soft “zero-feel” touch, and maximum durability against the elements.

- Avoid Heat Transfer for: Swimwear, as it creates a surface layer that can crack with stretching, fade in the sun, and feel stiff on performance fabrics.

What is Dye-Sublimation Printing?

Think of dye-sublimation as a permanent tattoo for fabric. It’s a sophisticated process that bonds the ink with the material on a molecular level, ensuring the design is as durable and soft as the fabric itself.

How It Works:

- Your custom design is first printed with special sublimation inks onto a sheet of transfer paper.

- This paper is placed onto the white swimwear fabric and both are put into a heat press.

- The heat and pressure work magic: the ink turns into a gas and permeates the polyester fibers of the fabric.

- As it cools, the ink turns back into a solid, becoming a permanent part of the material. The design is now in the fabric, not sitting on top of it.

Pros for Swimwear

- Zero Feel: Because the ink is inside the fabric fibers, the printed area feels just as soft and smooth as the rest of the material. There’s no texture, no stiffness—just pure comfort.

- Extreme Durability: A sublimated design will not crack, peel, or fade. It’s completely integrated into the garment, making it perfectly resistant to chlorine, saltwater, friction, and UV rays.

- Vibrant, Photo-Quality Colors: This method allows for an unlimited color palette, smooth gradients, and incredibly sharp, detailed designs. Your most complex and colorful patterns will look absolutely stunning.

- Breathability & Stretch: The process doesn’t clog the fabric’s pores or inhibit its flexibility. The material maintains its original breathability, moisture-wicking properties, and four-way stretch.

Cons for Swimwear

- It only works on polyester or high-polyester blend fabrics (which is perfect, as this is the standard for high-quality swimwear).

- For the most vibrant results, it must be performed on a white or light-colored base fabric.

What is Heat Transfer Printing?

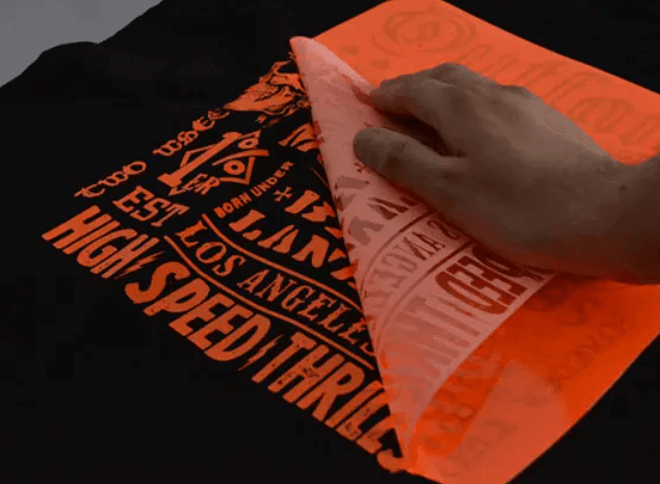

Think of heat transfer printing (often using Heat Transfer Vinyl or HTV) as a highly advanced, professional iron-on. It applies a design to the surface of a garment.

How It Works:

- The design is printed onto or cut from a sheet of special transfer material or vinyl.

- This printed layer is positioned on top of the fabric.

- A heat press is used to apply the design, melting an adhesive backing that bonds the design layer to the surface of the material. The result is a design that sits on top, like a very thin, flexible film.

Pros for Swimwear

- It is versatile and works on a wide variety of fabrics, including cotton, blends, and dark colors.

- It can be a cost-effective choice for very simple, small logos or graphics on swimwear.

Cons for Swimwear

- Noticeable Feel: You can physically feel the design on the fabric’s surface. This layer can feel stiff, rubbery, or plastic-like, which detracts from the comfort of sleek swimwear.

- Prone to Damage: This is the biggest issue for swimwear. The constant stretching of the fabric will cause the surface layer to crack over time. Chlorine and salt accelerate the breakdown of the adhesive, leading to peeling at the edges.

- Reduced Breathability: The solid transfer layer blocks the fabric’s natural weave, trapping moisture and heat against the skin.

- Color Limitations: While colors can be bright, this method is not as effective as sublimation for reproducing complex, photorealistic, or all-over patterns with fine detail.

Sublimation vs. Heat Transfer for Swimwear

Here’s a clear breakdown of how the two methods stack up for your custom swimwear:

| Feature | Dye-Sublimation | Heat Transfer |

| Durability | ✅ Excellent (Won’t crack, peel, or fade) | ❌ Poor (Prone to cracking and peeling with stretch) |

| Feel & Comfort | ✅ Perfect (Zero feel, part of the fabric) | ❌ Fair (Can feel stiff, like a layer on top) |

| Color Vibrancy | ✅ Excellent (Vibrant, unlimited colors, photo-quality) | ✅ Good (Vibrant, but less detail on complex designs) |

| Longevity | ✅ Permanent | ❌ Fades and degrades over time |

| Fabric Stretch | ✅ Unaffected | ❌ Can restrict stretch and crack when pulled |

| Area size | Medium to full-panel/all-over | Small to medium |

| Best For | All-over prints, custom designs, performance apparel | Simple logos on cotton t-shirts, promotional items |

Why Choose Sublimation

For swimwear, there is no contest. Dye-sublimation is the only printing method that meets the quality and performance standards that customers deserve.

A swimsuit is a high-performance garment. It needs to stretch, move with your body, and withstand the harshest elements without losing its beauty. You should never have to worry about a design that feels rough against your skin, cracks after a few wears, or fades by the end of summer.

This commitment to quality is why we exclusively use dye-sublimation for all our custom swimwear. We ensure that your design is not only stunningly vibrant but also incredibly durable and completely undetectable to the touch.

Frequently Asked Questions

Will my sublimated bikini design fade in the sun?

No. The dyes used in sublimation are infused deep into the fabric fibers, making them highly UV-resistant. Your design will maintain its brilliant color season after season.

Can you feel the print on a sublimated swimsuit?

No, you cannot. Because the design becomes part of the fabric itself, it has zero “hand feel.” The print is as soft, smooth, and flexible as the swimwear material.

Why can’t you sublimate on dark-colored fabric?

Sublimation is a dyeing process that adds color. Just as you can’t use a yellow highlighter on black paper and expect it to show up, the transparent sublimation dyes need a light base to display their true, vibrant colors.

Conclusion

While heat transfer printing has its place for other types of apparel, dye-sublimation is the undisputed professional standard for custom swimwear. It delivers unmatched durability, unparalleled comfort, and breathtaking vibrancy that simply can’t be achieved with a surface-level print.

At JoyBikini, we are dedicated to creating beautiful, long-lasting custom swimwear that you can wear with confidence, knowing your unique design is as resilient and stunning as you are.