Launching a swimwear line is an exhilarating venture. You have the designs, the brand vision, and the drive. But between your creative concept and a rack of sellable, high-quality swimsuits lies one of the most critical and often underestimated challenges: communicating effectively with your overseas manufacturer.

Miscommunication is more than just a frustration; it’s a direct threat to your bottom line. It leads to incorrect samples, production delays, wasted materials, and a final product that doesn’t match your vision.

Drawing on our 13 years of experience as a professional swimwear manufacturer, we’ve learned that effective communication not only builds trust but also helps reduce upfront development costs and streamline the entire production process.

This comprehensive guide offers a practical framework for clear, accurate, and culturally aware communication with overseas swimwear manufacturers.

Why Flawless Communication is Non-Negotiable

Before diving into the “how,” let’s establish the “why.” In the fast-paced world of fashion, effective communication with your supply chain is the bedrock of success.

- Quality Control: Your manufacturer can only produce what they understand. Ambiguity in your instructions directly translates to defects in the final product.

- Cost Management: Every incorrect sample and every production run that needs to be redone costs money. Clear communication minimizes errors, saving you thousands of dollars in the long run. The simple formula

(Number of Errors * Cost Per Error) = Wasted Capitalis a stark reminder of this. - Speed to Market: Delays caused by back-and-forth clarifications can cause you to miss selling seasons, handing a significant advantage to your competitors.

- Brand Reputation: A poorly made product can damage your brand’s reputation before it even gets off the ground. Your manufacturer is your partner in delivering on your brand’s promise of quality.

The Foundation: Pre-Communication Preparation

The best communication starts long before you send the first email. Thorough preparation is your greatest tool for preventing misunderstandings.

The Indispensable Tech Pack: Your Manufacturing Bible

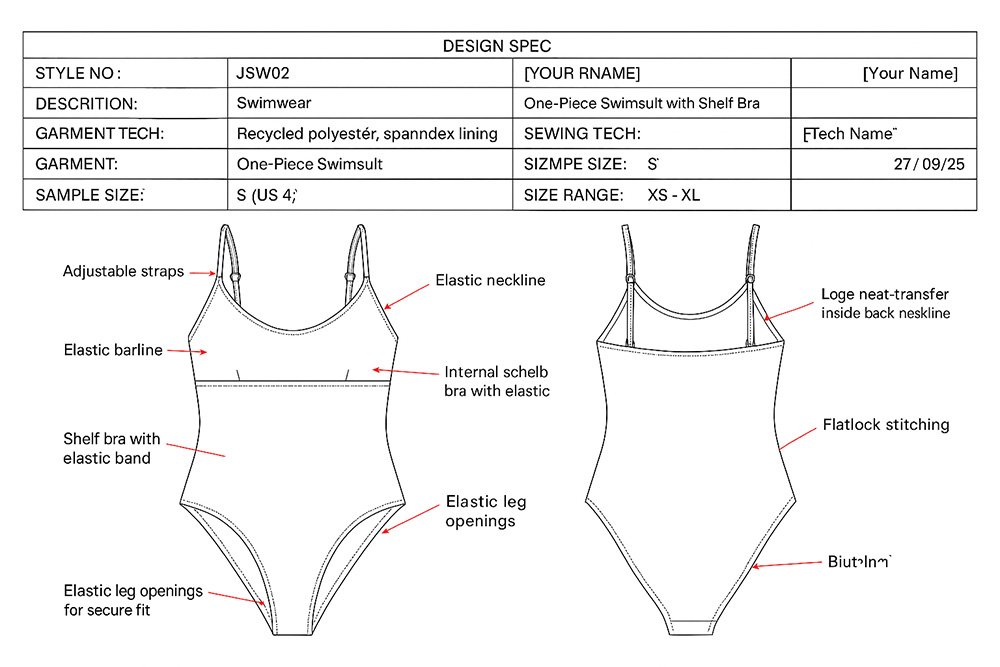

If you take only one thing away from this article, let it be this: you must have a detailed, professional tech pack. A tech pack (technical packet) is the universal language of the apparel industry. It is the single most important document you will create, serving as the blueprint for your design.

A weak or incomplete tech pack is the number one cause of manufacturing errors. Your tech pack should leave zero room for interpretation.

Essential Components of a Swimwear Tech Pack:

- Technical Flats: Detailed, black-and-white vector drawings of your garment from the front, back, and sometimes the side. These should show all stitching details, seams, and hardware placements.

- Bill of Materials (BOM): A complete list of every single component required to make the swimsuit. This includes:

- Main Body Fabric (e.g., 80% Nylon, 20% Spandex, 190 gsm)

- Lining Fabric

- Threads (color, thickness)

- Hardware (clasps, rings, sliders – with specific dimensions and finishes)

- Elastics (width, material)

- Labels (brand, care, size)

- Hygienic Liners

- Graded Size Chart (Spec Sheet): A table listing the precise measurements for every size you plan to produce (e.g., XS, S, M, L, XL). Include key points of measure like chest width, waist, hip, and strap length.

- Colorway Specifications: Clearly list the Pantone (TCX) color codes for every fabric and component for each color variation of the style. Do not just say “blue”; say “Pantone 19-4052 Classic Blue.”

- Construction Details: Written instructions explaining how the garment should be sewn. For example, “Coverstitch at leg openings with 3mm elastic” or “Zig-zag stitch on all top seams.” Use callouts on your technical flats to point to specific areas.

- Artwork & Print Details: If you have a custom print, include the print file in the correct format (e.g., vector AI file), repeat size, and placement instructions.

A detailed tech pack is your first line of defense against misinterpretation. It is your contract of expectations.

Overcoming Language and Cultural Barriers

Working with manufacturers in countries like China, Vietnam, or Indonesia often involves navigating significant language and cultural differences. Approaching this with awareness and strategy is key.

1. Keep Language Simple and Direct

Your contact person overseas likely speaks English as a second or third language. Avoid using slang, idioms, or overly complex sentence structures.

- Bad: “I was thinking maybe we could kick the tires on a slightly more vibrant shade for the lining, something that really pops but doesn’t fight the main print.”

- Good: “For the lining, please use Pantone 15-1335 ‘Vibrant Orange’. See attached image for reference.”

Use short sentences and bullet points wherever possible. This makes your communication scannable and easier to translate accurately.

2. A Picture is Worth a Thousand Words (and Dollars)

Visuals are a universal language. Supplement every written instruction with a visual aid.

- Annotate Photos: When providing feedback on a sample, take high-resolution photos. Circle the problem areas directly on the image and add short, clear notes.

- Use Videos: For complex construction issues or to demonstrate how a certain feature should function, a short video can be incredibly effective.

- Reference Garments: Send a physical “master sample” or a competitor’s garment that has a feature you want to replicate (like a specific type of stitching). This provides a tangible benchmark for quality.

3. Understand and Respect Cultural Nuances

Building a good working relationship can be invaluable.

- Be Patient and Polite: A direct, blunt “no” can be considered rude in some Asian cultures. Phrase feedback constructively. Instead of “This is wrong,” try “For the next sample, can we please adjust the strap length by 2cm to match the tech pack?”

- Be Aware of Holidays: Major holidays like Chinese New Year can shut down factories for weeks. Plan your production calendar around these events to avoid significant delays.

- Acknowledge Time Zones: Show respect by being mindful of your manufacturer’s working hours. A simple “I hope you are having a good morning/evening” can go a long way.

The Communication Workflow: A Step-by-Step Guide

Structure your communication around the key phases of production to maintain clarity and control.

Step 1: Initial Outreach and Vetting

When first contacting potential manufacturers, be professional and provide clear information. State your business name, describe your product (swimwear for women), mention your order quantity estimates (MOQs), and attach your tech pack. Ask specific questions about their experience with similar materials and styles.

How to find reliable swimwear manufacturer?

Step 2: The Sampling Process

This is the most communication-intensive phase. When you receive a sample:

- Measure it meticulously against your spec sheet.

- Document every single deviation in a list, referencing the tech pack.

- Provide feedback using the photo and video method described above.

- Consolidate all feedback into a single, organized email or document. Avoid sending multiple, scattered messages.

Step 3: Production and Quality Control (QC)

Before bulk production begins, approve a “Pre-Production Sample” (PPS). This is the final sample that will be used as the gold standard for the entire production run. Once you approve it, clearly state: “The PPS is approved. Please proceed with bulk production ensuring all units match this approved sample.”

Discuss your Quality Control plan. A common standard is the Acceptable Quality Limit (AQL). This is a statistical method that determines the maximum number of defective units acceptable in a production batch. Agreeing on an AQL level beforehand protects you from receiving a shipment of low-quality goods.

Step 4: Shipping and Logistics

Communication doesn’t end when production is finished. Confirm all shipping details:

- Packaging requirements (individual poly bags, carton dimensions, markings).

- Shipping terms (FOB, EXW).

- Correct shipping address and contact information.

- Request tracking information as soon as it’s available.

Final Best Practices for Seamless Communication

- Document Everything in Writing: While a quick chat on WhatsApp or WeChat is great for clarifying a small detail, always follow up with an email summarizing the conversation and any decisions made. This creates a paper trail that can be referenced later if disputes arise.

- Be Responsive: Answer your manufacturer’s questions promptly. A delay on your end can cause a production delay on their end.

- Never Assume: Never assume your manufacturer understands something that isn’t explicitly stated in your tech pack or written communication. If you want a specific type of thread used, specify it. If you need a certain fold for packaging, illustrate it. Over-communication is always better than under-communication.

By implementing these strategies, you shift from simply placing an order to managing a critical business partnership. Clear, respectful, and meticulously detailed communication is the single greatest investment you can make in the quality of your product and the health of your swimwear brand.